2010 ILLIG PET Coextruder + Inline ILLIG RDKp72g

2010 ILLIG PET Coextruder + Inline ILLIG RDKp72g

Available quantity:1

Description

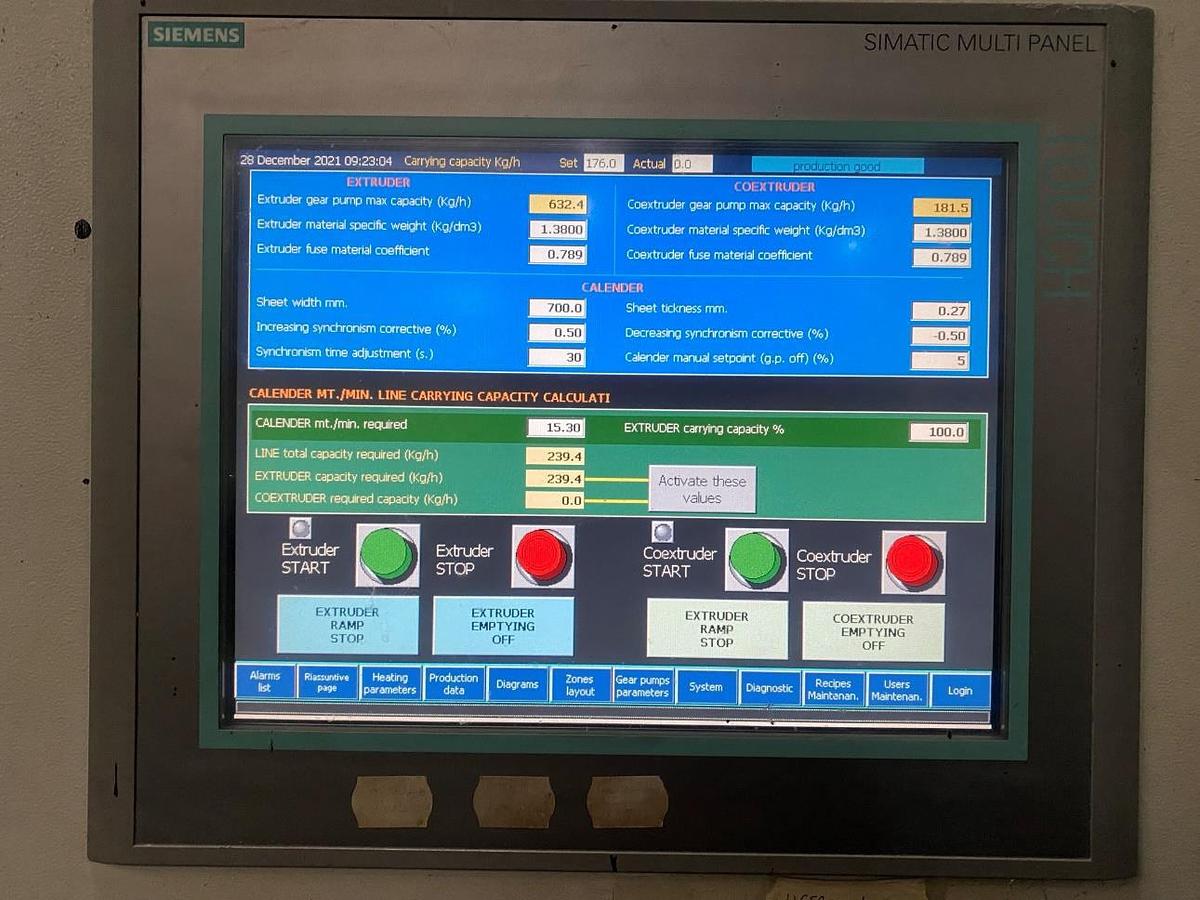

PET Coextrusion + Inline ILLIG RDKP72g Thermoforming Line, Age 2010, this equipment is suitable for PET, PP & PS Trays, Fruit & Vegetable baskets etc. :-

Inline S Plastic SRL PET Coextrusion line to produce pet sheet in-line with ILLIG RDKP72g 4-Station Thermoformer (www.samplastco.com. hole punch station) Age 2010 :

Maximum output 680 kg/ hr

Maximum sheet width 800 mm

The line includes:

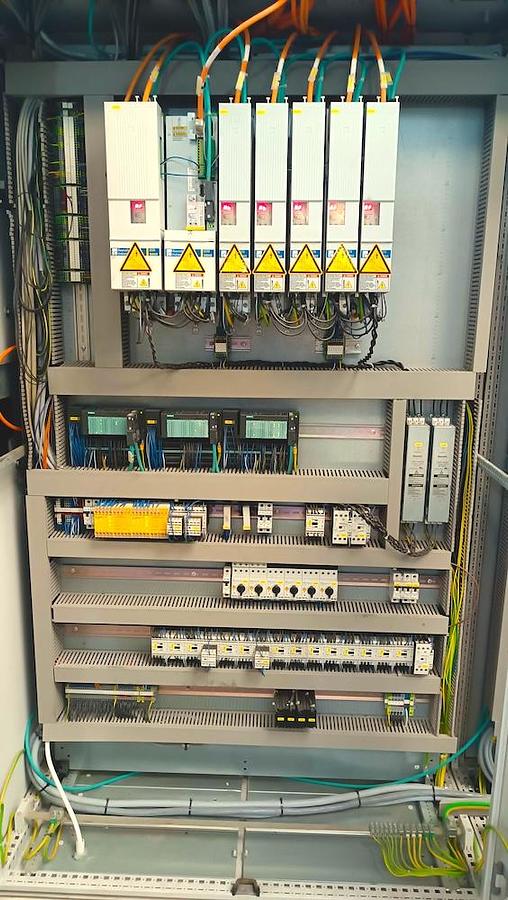

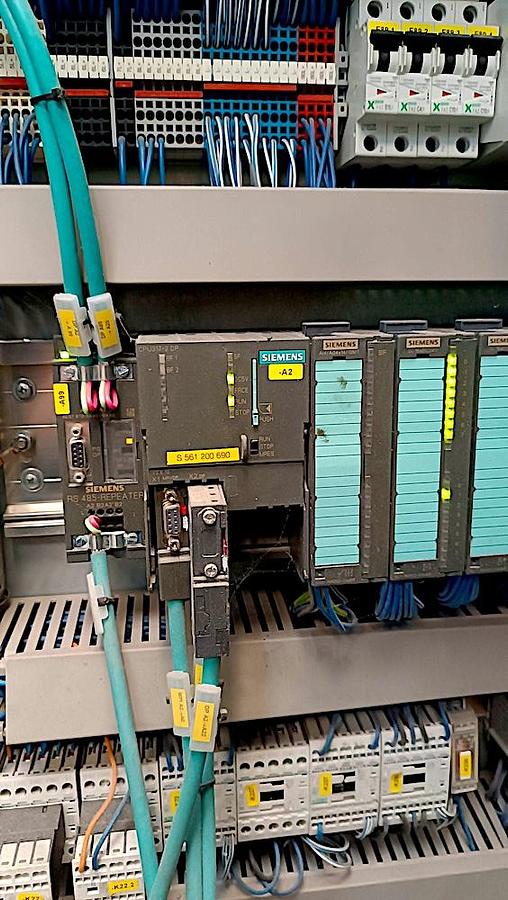

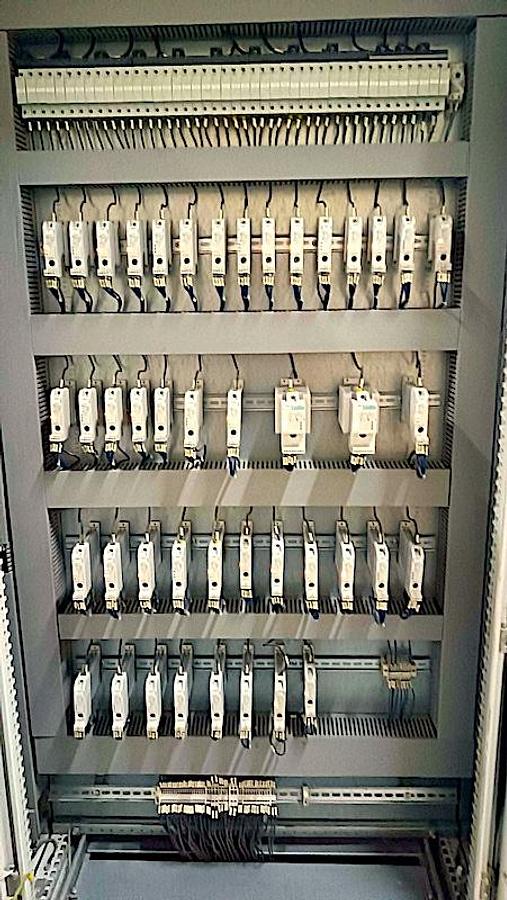

Electrical Control Panel

MSM Plastic Engineering Gravimetric Feeder, fed directly from the PET Dryer + additional Component for masterbatch or additive

Main extruder Model ED 100-40 dia. Ø100 mm, L/D 40

BP Plast BDO X2 100 Double plate hydraulic screen changer

MAAG Gear pump

Co-extruder Model E60-40 dia. Ø60 mm, L/D 40 with Gravimetric feeder

BP Plast Single plate hydraulic screen changer

MAAG Gear pump

3- Layer (ABA) Melt Feed Adapter

Special extrusion die for PET, width 900 mm

3-Roll Polished Chrome Calendering Unit

Width 1000 mm, Top Roll dia. Ø350 mm, Lower two Roll dias. Ø500 mm

Model: CD500AT1200

Thermoregulating cooling control unit for the Calender

Green Box (now FRIGEL)

Model: TG-P3/3/12/130

MSM Plastics Division, Dryer for PET

Model: WIND 125

Age 2011

Installed power: 19kW

Amp 31.5 A

Siemens SIMATIC MULTI PANEL Color Operator Control Panel, Siemens S& PLC Controls

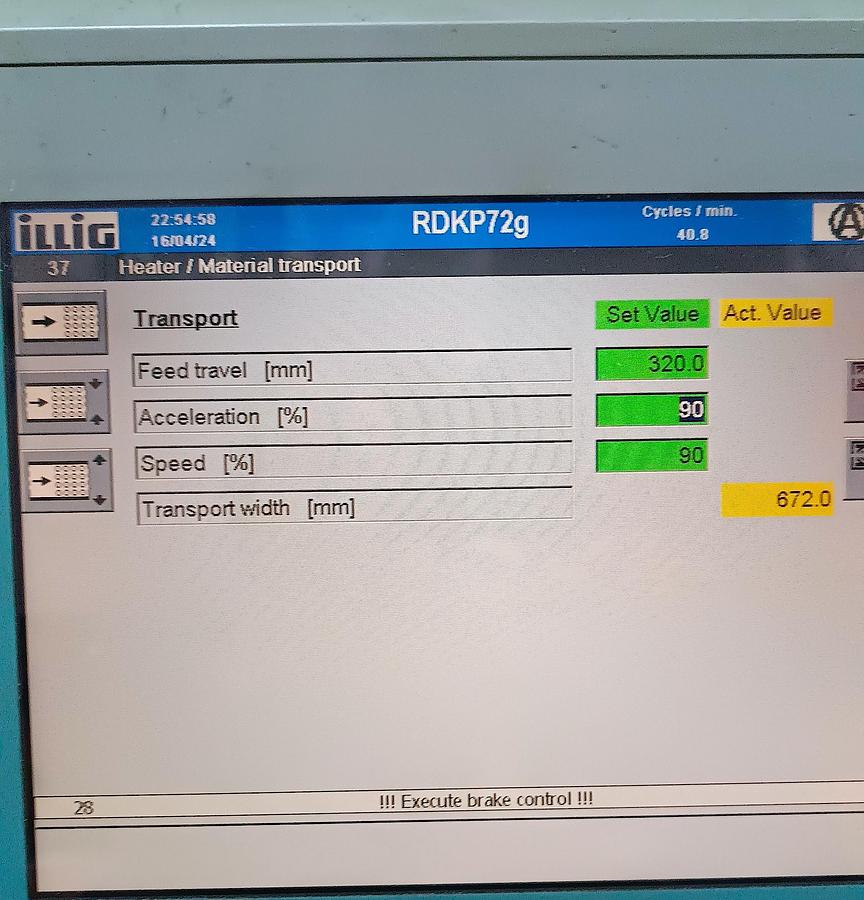

Inline ILLIG RDKP72g full Servomotor 4-Station Thermoformer, age 2010

Double Heating Oven

Top heater 37,1 kW

Bottom heater 37,1 kW

Bosch REXROTH Indexing Servomotor

Form Station with Toggles and Servomotors on both Top and Bottom Form Plattens

Forming area with pneumatic clamping frame max. 671 x 535 mm

Material width with/ without sprung clamping frame max. 805 mm

Material thickness (varies with material type) max. 2.5 mm

Material transport accuracy ± 0.2 mm

Feed length max. 553 mm

Feed length min. 150 mm

Moulding height above material level, max. 120 mm

Formed part height beneath material level max. 120 mm

Total formed part height max. 120 mm

Sheet Sag Control

Transport Rail auto-spreading for PP

Servomotor Hole Punch Station

Servomotor Steel Rule Die Punching Station

Servomotor Stacking/ Counting Station

Cycle rate max. 40 rpm

Total electrical connection - Standard (Option) 85.4 (86.6) kW

Siemens S7 PLC

Skeletal Waste Material Winder

Inline ILLIG RS75b Grinder with Blower ILLIG FD74

Specifications

| Manufacturer | ILLIG |

| Model | PET Coextruder + Inline ILLIG RDKp72g |

| Year | 2010 |

| Condition | Used |

| Stock Number | 614 |